Biogas plants

---------------

Type of Biogas Plants: - Numerous models of Biogas plants are available in India. These are grouped under two categories;

1) Floating gas holder plant /Floating dome biogas plant

Ex: KVIC type Biogas plant

(KVIC: Khadi and Village Industries Commission)

2) Fixed dome Biogas plant

a. Janta Biogas plant

b. Deenbandhu Biogas plant

1) Floating gas holder plant

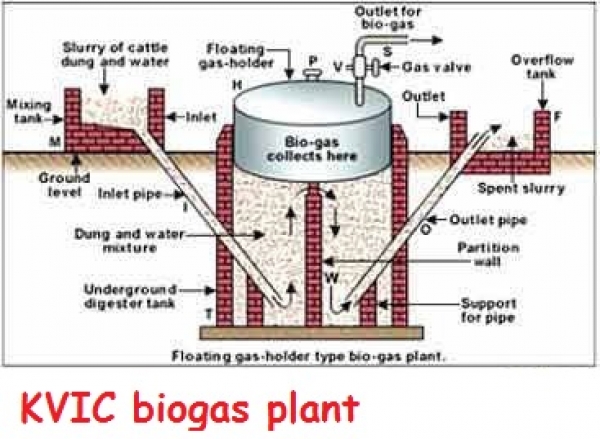

Name: KVIC – type biogas plant

Theory:

The KVIC biogas plant was the first application of biogas plant in India which was developed in 1954, after which all other types of biogas plants were introduced. It is known as KVIC plant because, the application of the KVIC plant in the villages was started in year 1962 by Khadi and Village Industry Commission, Bombay.

The available designs are varies in the size from 1 m3 to 140 m3 gas per day. The main design principle is that, it consists of a digester or pit for fermentation and a floating drum for the collection of gas. Digester is 3.5 to 6.5 m in depth and 1.2 to 1.6 m in diameter. There is a partition wall in center, which divides the digester vertically and submerges the slurry when it is full. The digester is connected to the inlet and outlet by two pipes. Through the inlet, the dung is mixed with water (4:5) and loaded into the digester. The fermented material will flow out through outlet pipe. The outlet is generally connected to a compost pit. The gas generation takes place slowly in two stages. In the first stage, the complex organic substances contained in the waste are acted upon by a certain kind of bacteria, called acid formers and broken up into small-chain simple acids. In the second stage, these acids are acted upon by another kind of bacteria, called methane formers and produce methane and carbon dioxide.

Floating Dome Biogas Plant

KVIC Biogas Plant

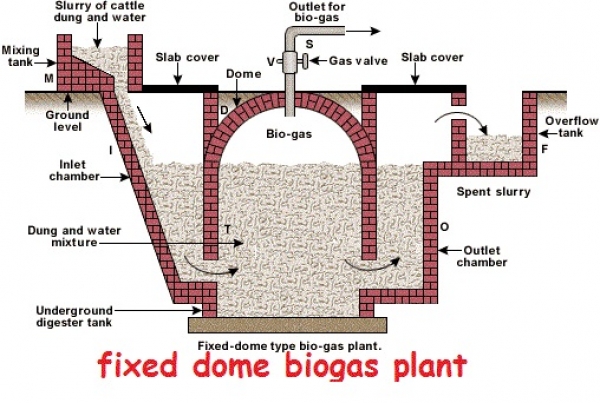

1) Fixed dome Biogas plant /Fixed drum type Biogas plant

a) Name: Janta Biogas plant

Theory:

The fixed dome model which is also called a Chinese plant has been introduced under the name “Janta biogas plant” by Gobar Gas Research Station,Ajitmal in view of it reduced cost. In this plant the digester is made up of masonry and the gas holder made up of M.S. Plate. This is a complete masonry structure. Where no steel is used. Due to the specialized design good quality of bricks and cement is used & skilled worker are required to prevent it from the problems like cracking of the dome & leakage of gas.

This model has longer and higher capacity with compared to KVIC model; hence it can be used as community biogas plant. The materials used in this type of model are cattle dung, municipal waste and plant residual. The plant consists of an underground well sort of digester model of bricks and cement having a dome shaped roof which remains below the ground level. At the middle of the digester, there are two rectangular openings facing each other and coming up to a little above the ground level, act as an in let and out let of the plant. Dome shaped roof is fitted with a pipe at its top which is the gas out let of the plat. The principle of gas production is some as the KVIC model. The biogas is collected in the restricted space of the fixed dome; hence the pressure of gas is much higher, which is around 90 cm of water column.

Fixed Dome Biogas Plant

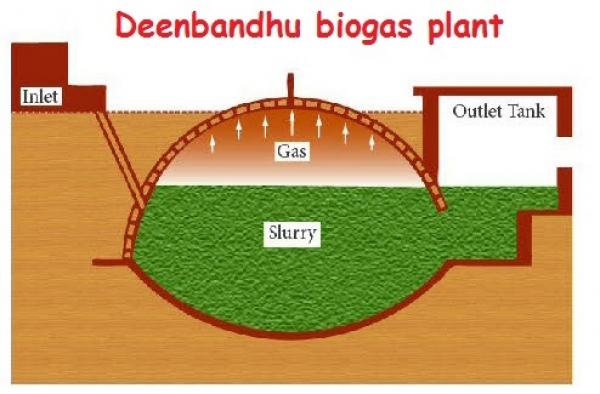

b) Name: Deenbandhu biogas plant

Deenbandhu model is a fixed dome biogas plant developed in 1984 by Action for Food Production (AFPRO), New Delhi. Due to the cost effectiveness (low cost), it is very popular in rural areas. The cost reduction has been achieved by minimizing the surface area through joining the segments of two spheres of different diameters at their bases. The cost of a Deenbandhu plant having a capacity of 2 m3/day is about Rs. 8000 /-.

Deenbandhu Biogas PlantTheory:

The foundation of the plant is constructed in the segment of spherical shape. On the outer periphery of this foundation, the dome shaped digester is constructed with same base diameter. Therefore the digester, gas portion and dome look as a single unit. The surface area of the biogas plant is reduced with same digester volume reducing the earth work and cost of construction without scarifying the efficiency.

This type of plant has a hemispherical fixed-dome type of gas holder, unlike the floating dome of the KVIC-design. The dome is made from pre-fabricated Ferro-cement or reinforced concrete and attached to the digester, which has a curved bottom. The slurry is fed from a mixing tank through an inlet pipe connected to the digester. After fermentation the biogas collects in the space under the dome. It is taken out for use through a pipe connected to the top of the dome while the sludge, which is a by-product comes out through an opening in the side of the digester. About 90 percent of the biogas plants in India are of the Deenbandhu type.