Grading:

-------

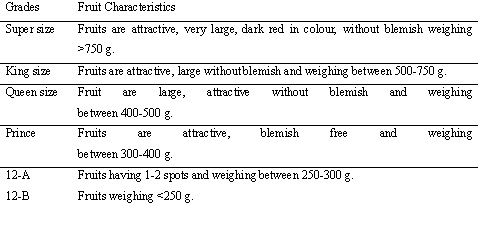

The fruits after harvesting are graded as per their colour, size and weight. The different grades are as follows-

Packing:

-------

All the graded fruits are wrapped in paper and packed in corrugated fibreboard (CFB) boxes. Brown coloured 3 fold CFB boxes are used for local market while, white coloured 5 fold CFB boxes are used for distant markets. Paper shreds are used as padding material. For `Super` and `King` grades, boxes of size 32.5 x 22.5 x 10 cm are used. `Queen` grade fruits are packed in 37.5 x 27.5 x 10 cm size boxes while `Prince` and `12-A` grades are packed in 35 x 25 x 10 cm size boxes.

Storage:

-------

Fruits can be stored at 5°C with 90-95% relative humidity for 2 months. In case of storage beyond two months, temperature should be maintained at 10°C to avoid chilling injury. Pomegranates are very susceptible to water loss resulting in shriveling of the skins. Storing fruit in plastic liners and waxing can reduce water loss, especially under conditions of lower relative humidity.

Cool Chain:

----------

Cool chain is essential during the transport of export quality commodity all the way from the farm to the customer. This helps in maintaining the temperature inside the box at the same low level as in the cold storage.

The various stages of the cool chain are :

• Coldstore at the farm.

• Refrigerated truck from farm to the airport

• Coldstore at the airport.

• Building up of the pallet in a coldstore at the airport.

• Loading the aircrafts directly from the coldstore in a short time.

• Cargo aircraft maintains coldstore temperature in hold.

• Off loading direct into a coldstore in the receiving country.

• Refrigerated truck to the customers.

Marketing:

---------

• Several intermediaries like wholesalers and commission agents are involved in marketing of the fruit. The farmer realizes around 35% of the wholesale .price in the secondary market.