Classification of Greenhouses

-------------------------------

Greenhouse structures of various types are used successfully for crop production. Although there are advantages in each type for a particular application, in general there is no single type greenhouse, which can be considered as the best. Different types of greenhouses are designed to meet the specific needs.

1.1 Greenhouse type based on shape

Greenhouses can be classified based on their shape or style. For the purpose of classification, the uniqueness of the cross section of the greenhouses can be considered as a factor. As the longitudinal section tend to be approximately the same for all types, the longitudinal section of the greenhouse cannot be used for classification. The cross sections depict the width and height of the structure and the length is perpendicular to the plane of cross section. Also, the cross section provides information on the overall shape of the structural members, such as truss or hoop, which will be repeated on every bay. The commonly followed types of greenhouse based on shape are lean-to, even span, uneven span, ridge and furrow, saw tooth and Quonset.

1.1.1 Lean-to type greenhouse

A lean-to design is used when a greenhouse is placed against the side of an existing building. It is built against a building, using the existing structure for one or more of its sides . It is usually attached to a house, but may be attached to other buildings. The roof of the building is extended with appropriate greenhouse covering material and the area is properly enclosed. It is typically facing south side. The lean-to type greenhouse is limited to single or double-row plant benches with a total width of 7 to 12 feet. It can be as long as the building it is attached to. It should face the best direction for adequate sun exposure. The advantage of the lean-to type greenhouse is that, it usually is close to available electricity, water, and heat. It is a least expensive structure. This design makes the best use of sunlight and minimizes the requirement of roof supports.

It has the following disadvantages:

limited space, limited light, limited ventilation and temperature control. The height of the supporting wall limits the potential size of the design. Temperature control is more difficult because the wall that the greenhouse is built on, may collect the sun`s heat while the translucent cover of the greenhouse may lose heat rapidly. It is a half greenhouse, split along the peak of the roof.

Lean to Greenhouse

Lean to Greenhouse

Lean to Greenhouse

1.1.2 Even span type greenhouse

The even-span is the standard type and full-size structure, the two roof slopes are of

equal pitch and width . This design is used for the greenhouse of small size, and it is constructed on level ground. It is attached to a house at one gable end. It can accommodate 2 or 3 rows of plant benches. The cost of an even-span greenhouse is more than the cost of a lean-to type, but it has greater flexibility in design and provides for more plants. Because of its size and greater amount of exposed glass area, the even-span will cost more to heat. The design has a better shape than a lean-to type for air circulation to maintain uniform temperatures during the winter heating season. A separate heating system is necessary unless the structure is very close to a heated building. It will house two side benches, two walks, and a wide center bench. Several single and multiple span types are available for use in various regions of India. For single span type the span in general, varies from 5 to 9 m, whereas the length is around 24 m. The height varies from 2.5 to 4.3 m.

Even Span Type Green House

Even Span Type Green House

1.1.3 Uneven span type greenhouse

This type of greenhouse is constructed on hilly terrain. The roofs are of unequal width; which make the structure adaptable to the side slopes of hill. This type of greenhouse is seldom used now-a-days as it is not adaptable for automation.

1.1.4 Ridge and furrow type greenhouse

Designs of this type use two or more A-frame greenhouses connected to one another

along the length of the eave. The eave serves as furrow or gutter to carry rain and melted snow away. The side wall is eliminated between the greenhouses, which results in a structure with a single large interior, Consolidation of interior space reduces labour, lowers the cost of automation, improves personal management and reduces fuel consumption as there is less exposed wall area through which heat escapes. The snow loads must be taken into account in the frame specifications of these greenhouses since the snow cannot slide off the roofs as in case of individual free standing greenhouses, but melts away. In spite of snow loads, ridge and furrow greenhouses are effectively used in northern countries of Europe and in Canada and are well suited to the Indian conditions.

Ridge and Furrow Type Greenhouse

1.1.5 Saw tooth type Greenhouse

These are also similar to ridge and furrow type greenhouses except that, there is provision for natural ventilation in this type. Specific natural ventilation flow path develops in a saw- tooth type greenhouse.

Saw Tooth Type Green House

1.1.6 Quonset greenhouse

This is a greenhouse, where the pipe arches or trusses are supported by pipe purlins running along the length of the greenhouse. In general, the covering material used for this type of greenhouses is polyethylene. Such greenhouses are typically less expensive than the gutter connected greenhouses and are useful when a small isolated cultural area is required. These houses are connected either in free standing style or arranged in an interlocking ridge and furrow.

In the interlocking type, truss members overlap sufficiently to allow a bed of plants to grow between the overlapping portions of adjacent houses. A single large cultural space thus exists for a set of houses in this type, an arrangement that is better adapted to the automation and movement of laborers.

Quonset Green House

Quonset Green House

1.2 Greenhouse type based on utility

Classification of greenhouses can be made depending on the functions or utilities. Of the different utilities, artificial cooling and heating of the greenhouse are more expensive and elaborate. Hence based on the artificial cooling and heating, greenhouses are classified as greenhouses for active heating system and for active cooling system.

1.2.1 Greenhouses for active heating

During the night time, air temperature inside greenhouse decreases. To avoid the cold bite to plants due to freezing, some amount of heat has to be supplied. The requirements for heating greenhouse depend on the rate at which the heat is lost to the outside environment. Various methods are adopted to reduce the heat losses, viz., using double layer polyethylene, thermo pane glasses (Two layers of factory sealed glass with dead air space) or to use heating systems, such as unit heaters, central heat, radiant heat and solar heating system.

1.2.2 Greenhouses for active cooling

During summer season, it is desirable to reduce the temperatures of greenhouse than the ambient temperatures, for effective crop growth. Hence suitable modifications are made in the greenhouse so that a large volume of cooled air is drawn into greenhouse. This type of greenhouse either consists of evaporative cooling pad with fan or fog cooling. This greenhouse is designed in such a way that it permits a roof opening of 40% and in some cases nearly 100%.

1.3 Greenhouse type based on construction

The type of construction is predominantly influenced by the structural material, though the covering material also influences the type. Span of the house in turn dictates the selection of structural members and their construction. Higher the span, stronger should be the material and more structural members are used to make sturdy truss type frames. For smaller spans, simpler designs like hoops can be followed. Therefore based on construction, greenhouses can be broadly classified as wooden framed, pipe framed and truss framed structures.

1.3.1 Wooden framed structures

In general, for the greenhouses with span less than 6 m, only wooden framed structures are used. Side posts and columns are constructed of wood without the use of a truss. Pine wood is commonly used as it is inexpensive and possesses the required strength. Timber locally available, with good strength and durability also can be used for the construction.

Wooden Frame Structure

Timber Frame Greenhouse

Wooden Frame Structure

1.3.2 Pipe framed structures

Pipes are used for construction of greenhouses, when the clear span is around 12m . In general, the side posts, columns, cross ties and purlins are constructed using pipes. In this type, the trusses are not used. The pipe components are not interconnected but depend on the attachment to the sash bars for support.

Pipe Framed Structure

Pipe Framed Structure1.3.3 Truss framed structures

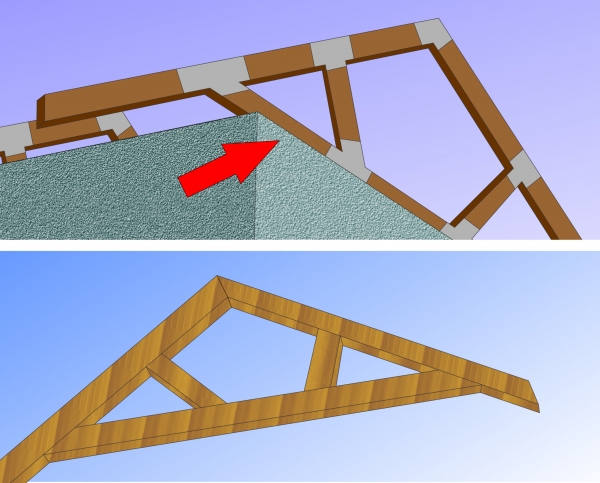

If the greenhouse span is greater than or equal to 15m, truss frames are used. Flat steel, tubular steel or angular iron is welded together to form a truss encompassing rafters, chords and struts. Struts are support members under compression and chords are support members under tension. Angle iron purlins running throughout the length of greenhouse are bolted to each truss. Columns are used only in very wide truss frame houses of 21.3 m or more. Most of the glass houses are of truss frame type, as these frames are best suited for pre-fabrication.

Truss Framed Structures

Truss Framed Structures

Wood Truss

1.4 Greenhouse type based on covering materials

Covering materials are the major and important component of the greenhouse structure. Covering materials have direct influence on the greenhouse effect inside the structure and they alter the air temperature inside the house. The types of frames and method of fixing also varies with the covering material. Based on the type of covering materials, the greenhouses are classified as glass, plastic film and rigid panel greenhouses.

1. 4.1 Glass greenhouses

Only glass greenhouses with glass as the covering material existed prior to 1950. Glass as covering material has the advantage of greater interior light intensity. These greenhouses have higher air infiltration rate which leads to lower interior humidity and better disease prevention. Lean-to type, even span, ridge and furrow type of designs are used for construction of glass greenhouse.

Glass Green Houses

Glass Green Houses

1.4.2 Plastic film greenhouses

Flexible plastic films including polyethylene, polyester and polyvinyl chloride are used as covering material in this type of greenhouses. Plastics as covering material for greenhouses have become popular, as they are cheap and the cost of heating is less when compared to glass greenhouses. The main disadvantage with plastic films is its short life. For example, the best quality ultraviolet (UV) stabilized film can last for four years only. Quonset design as well as gutter-connected design is suitable for using this covering material.

Plastic Film Green House

Plastic Film Green House

1.4.3 Rigid panel greenhouses

Polyvinyl chloride rigid panels, fibre-glass reinforced plastic (FRP), acrylic and polycarbonate rigid panels are employed as the covering material in the Quonset type frames or ridge and furrow type frames. This material is more resistant to breakage and the light intensity is uniform throughout the greenhouse when compared to glass or plastic. High grade panels have long life even up to 20 years. The main disadvantage is that these panels tend to collect dust as well as to harbor algae, which results in darkening of the panels and subsequent reduction in the light transmission. There is significant danger of fire hazard.

1.5 Shading nets

There are a great number of types and varieties of plants that grow naturally in the most diverse climate conditions that have been transferred by modern agriculture from their natural habitats to controlled crop conditions. Therefore, conditions similar to the natural ones must be created for each type and variety of plant. Each type of cultivated plant must be given the specific type of shade required for the diverse phases of its development. The shading nets fulfill the task of giving appropriate micro-climate conditions to the plants. Shade nettings are designed to protect the crops and plants from UV radiation, but they also provide protection from climate conditions, such as temperature variation, intensive rain and winds. Better growth conditions can be achieved for the crop due to the controlled microclimate conditions “created” in the covered area, with shade netting, which results in higher crop yields. All nettings are UV stabilized to fulfill expected lifetime at the area of exposure. They are characterized of high tear resistance, low weight for easy and quick installation with a 30-90% shade value range. A wide range of shading nets are available in the market which are defined on the basis of the percentage of shade they deliver to the plant growing under them.

Shading Net House

Shading Net House