Green – House Cooling System

--------------------------------

Fan and Pad cooling system

Precise control of various parameters of greenhouse environment is necessary to optimize energy inputs and thereby maximize the economic returns. Basically, the objective of environmental control is to maximize the plant growth. The control of greenhouse environment means the control of temperature, light, air composition and nature of the root medium. A greenhouse is essentially meant to permit at least partial control of microclimate within it. Obviously greenhouses with partial environmental control are more common and economical. From the origin of greenhouse to the present there has been a steady evolution of controls. Five stages in this evolution include manual controls, thermostats, step-controllers, dedicated micro processors and computers. This chain of evolution has brought about a reduction in control labour and an improvement in the conformity of greenhouse environments to their set points. The benefits achieved from greenhouse environmental uniformity are better timing and good quality of crops, disease control and conservation of energy.

Greenhouse Cooling

Greenhouse ventilation and cooling of greenhouse environment is essential during summer and winter as well. While summer cooling is done using evaporative cooling systems, the winter cooling uses convection tube with pressurizing fans and exhaust fans. Greenhouse cooling requires that large volume of air to be brought into the greenhouse.

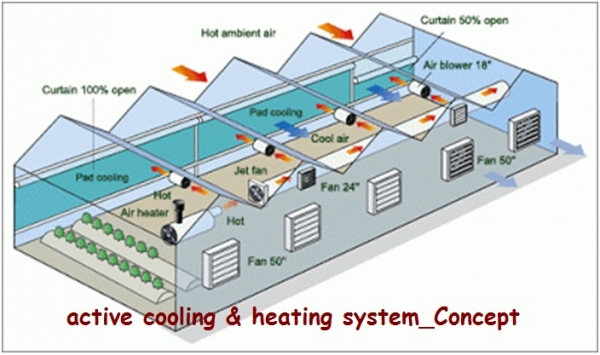

Active Cooling & Heating System Concept

1.1 Active summer cooling systems

Active summer cooling is achieved by evaporative cooling process .The evaporative cooling systems developed are to reduce the problem of excess heat in greenhouse. In this process cooling takes place when the heat required for moisture evaporation is derived from the surrounding environment causing a depression in its temperature. The two active summer cooling systems, presently in use, are ‘fan-and-pad’ and ‘fog’ systems. In the evaporative cooling process the cooling is possible only up to the wet bulb temperature of the incoming air.

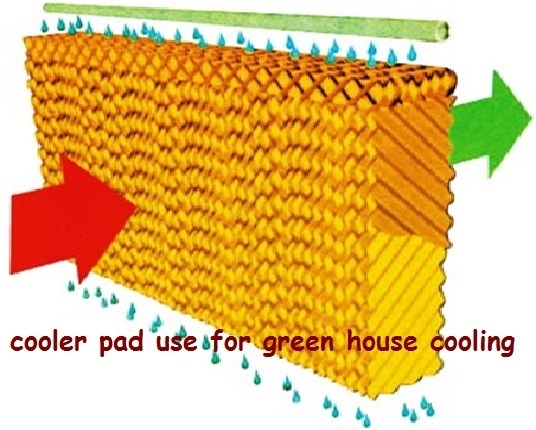

1.1.1 Fan and Pad cooling system

The fan and pad evaporative cooling system has been available since 1954 and is still the

most common summer cooling system in greenhouses. Along one wall of the greenhouse, water is passed through a pad that is usually placed vertically in the wall. Traditionally, the pad was composed of excelsior (wood shreds), but today it is commonly made of a cross-fluted-cellulose material, somewhat similar in appearance to corrugated card board. Exhaust fans are placed on the opposite wall. Warm outside air is drawn in through the pad. The supplied water in the pad, through the process of evaporation, absorbs heat from the air passing through the pad as well as from surroundings of the pad and frame, thus causing the cooling effect. Khus-khus grass mats can also be used as cooling pads.

Cooler Pad Use For Green House Cooling

Pad In Green House For Cooling

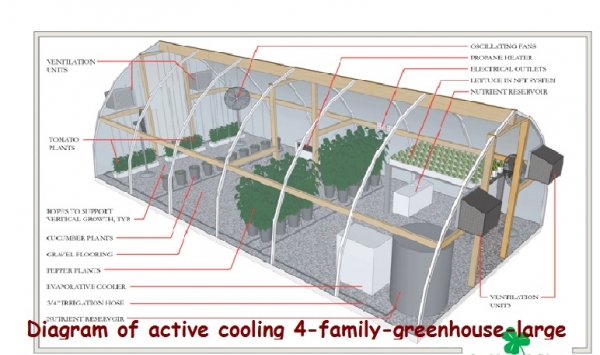

Diagram of Active Cooling

1.1.2 Fog cooling system

The fog evaporative cooling system, introduced in greenhouses in 1980, operates on the same cooling principle as the fan and pad cooling system but uses quite different arrangement. A high pressure pumping apparatus generates fog containing water droplets with a mean size of less than 10 microns using suitable nozzles. These droplets are sufficiently small to stay suspended in air while they are evaporating. Fog is dispersed throughout the greenhouse, cooling the air everywhere. As this system does not wet the foliage, there is less scope for disease and pest attack. The plants stay dry throughout the process. This system is equally useful for seed germination and propagation since it eliminates the need for a mist system. Both types of summer evaporative cooling system can reduce the greenhouse air temperature.

Fogger

Over Head Irrigation By Fogger

1.2 Active winter cooling systems

Excess heat can be a problem during the winter. In the winter, the ambient temperature will be below the desired temperature inside the greenhouse. Owing to the greenhouse effect, the entrapment of solar heat can rise the temperature to an injurious level; if the greenhouse is not ventilated. The actual process in winter cooling is tempering the excessively cold ambient air before it reaches the plant zone. Otherwise, hot and cold spots in the greenhouse will lead to uneven crop timing and quality .This mixing of low temperature ambient air with the warm inside air cools the greenhouse in the winter. Two active winter cooling systems, commonly employed, are convection tube cooling and horizontal air flow (HAF) fan cooling systems.

1.2.1 Convection tube cooling

The general components of convection tube are the louvered air inlet, a polyethylene convection tube with air distribution holes, a pressurizing fan to direct air in to the tube under pressure, and an exhaust fan to create vacuum. When the air temperature inside the greenhouse exceeds the set point, the exhaust fan starts functioning thus creating vacuum inside the greenhouse. The louver of the inlet in the gable is then opened through which cold air enters due to the vacuum. The pressurizing fan, at the end of the clear polyethylene convection tube, operates to pick up the cool air entering the louver. A proper gap is available for the air entry, as the end of the convection tube is separated from the louvered inlet by 0.3 to 0.6m and the other end of the tube is sealed. Round holes of 5 to 8 cm in diameter are provided in pairs at opposite sides of the tube spaced at 0.5 to 1m along the length of the tube.

Cold air under pressure in the convection tube shoots out of holes on either side of the tube in turbulent jets. In this system, the cold air mixes with the warm greenhouse air well above the plant height. The cool mixed air, being heavier, gently flows down to the floor level, and affects the complete cooling of the plant area. The pressurizing fan forcing the incoming cold air in to the convection tube must be capable of moving at least the same volume of air as that of the exhaust fan, thereby avoiding the development of cold spots in the house. When cooling is not required, the inlet louver closes and the pressurizing fan continues to circulate the air within the greenhouse. The process minimizes the temperature gradient at difference levels. The circulation of air using convection tube consumes more power than a circulation system.

Convection Tube

1.2.2 Horizontal air flow cooling

HAF cooling system uses small horizontal fans for moving the air mass and is considered to be an alternative to convection tube for the air distribution. In this method the greenhouse may be visualized as a large box containing air and the fans located strategically moves the air in a circular pattern. This system should move air at 0.6 to 0.9 m3/min/m2 of the greenhouse floor area. Fractional horse power of fans is 31 to 62 W (1/30 to 1/15hp) with a blade diameter of 41cm are sufficient for operation. The fans should be arranged in such a way that air flows are directed along the length of the greenhouse and parallel to the ground. The fans are placed at 0.6 to 0.9m above plant height and at intervals of 15m.They are arranged such that the air flow is directed by one row of the fans along the length of the greenhouse down one side to the opposite end and then back along the other side by another row of fans .Greenhouses of larger widths may require more number of rows of fans along its length. Temperatures at plant height are more uniform with HAF system than with convection tube system. The HAF system makes use of the same exhaust fans, inlet louvers and controls as the convection tube system. The only difference is the use of HAF fans in place of convection tubes for the air distribution. Cold air entering through the louvers located at the higher level in the gables of the greenhouse is drawn by the air circulation created by the net work of HAF fans and to complete the cycle, proper quantity of air is let out through the exhaust fans. The combined action of louvered inlet, HAF fans and the exhaust fans distribute the cold air throughout the greenhouse. Similarly, the convection tubes and the HAF fans can be used to distribute heat in the greenhouse. When neither cooling nor heating is required, the HAF fans or convection tube can be used to bring warm air down from the upper level of the gable and to provide uniform temperature in the plant zone. It is possible to integrate summer and winter cooling systems with heating arrangements inside a greenhouse for the complete temperature control requirements for certain days of the season.

Horizontal Fan Cooling System In Green House

1.3 Greenhouse ventilation

Ventilation is the process of allowing the fresh air to enter in to the enclosed area by driving out the air with undesirable properties. In the greenhouse context, ventilation is essential for reducing temperature, replenishing CO2 and controlling relative humidity. Ventilation requirements for greenhouses vary greatly, depending on the crop grown and the season of production. The ventilation system can be either a passive system (natural Ventilation) or an active system (forced ventilation) using fans. Usually greenhouses that are used seasonally employ natural ventilation only. The plant response to specific environment factor is related to the physiological processes and hence the latter affects the yield and quality. Hence, controlling of environment is of great importance to realize the complete benefits of CEA (Controlled Environment Agriculture). Manual maintenance of uniform environmental condition inside the greenhouse is very difficult and cumbersome. A poor maintenance results in less crop production, low quality and low income. For effective control of automatic control systems, micro processor and computer are used presently to maintain the environment.

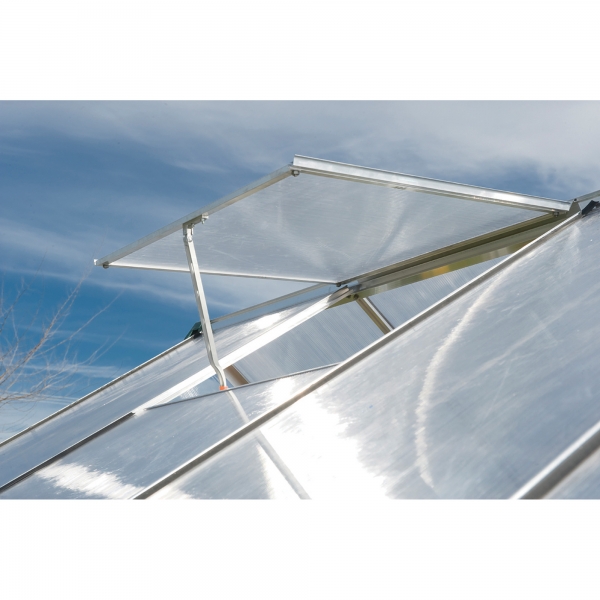

1.3.1 Natural ventilation

In the tropics, the sides of greenhouse structures are often left open for natural ventilation. Tropical greenhouse is primarily a rain shelter, a cover of polyethylene over the crop to prevent rainfall from entering the growing area. This mitigates the problem of foliage diseases. Ventilators are located on both roof slopes adjacent to the ridge and also on both side walls of the greenhouse. The ventilators on the roof as well as those on the side wall accounts, each about 10% of the total roof area. During winter cooling phase, the south roof ventilator is opened in stages to meet cooling needs. When greater cooling is required, the north ventilator is opened in addition to the south ventilator. In summer cooling phase, the south ventilator is opened first, followed by the north ventilator. As the incoming air moves across the greenhouse, it is warmed by sunlight and by mixing with the warmer greenhouse air. With the increase in temperature, the incoming air becomes lighter and rises up and flows out through the roof ventilators. This sets up a chimney effect , which in turn draws in more air from the side ventilators creating a continuous cycle. This system does not adequately cool the greenhouse. On hot days, the interior walls and floor are frequently injected with water to help cooling.

Natural Ventilation for Green House

Roof Ventilation System

1.3.1.1 Roll up side passive ventilation in poly houses

Roll up method of ventilation, allows the air to flow across the plants. The amount of ventilation on one side, or both sides, may be easily adjusted in response to temperature, prevailing wind and rain. During the periods of excessive heat, it may be necessary to roll the sides up almost to the top. Passive ventilation can also be accomplished by manually raising or parting the polyethylene sheet. The open vent areas must be covered with screens to prevent virus diseases. The holes must be large enough to permit free flow of air. Screens with small holes block air movement and cause a build up of dust. Rollup side passive ventilation on plastic greenhouses is only effective on free standing greenhouses and not on gutter connected greenhouses.

Roll Up Side Passive Ventilation In Poly Houses

Roll Up Side Passive Ventilation In Poly Houses

1.3.2 Forced Ventilation

In forced or active ventilation, mechanical devices such as fans are used to expel the air. This type of ventilation can achieve uniform cooling. These include summer fan-and-pad and fog cooling systems and the winter convection tube and horizontal airflow systems. For mechanical ventilation, low pressure, medium volume propeller blade fans, both directly connected and belt driven are used for greenhouse ventilation. They are placed at the end of the green house, opposite to the air intake, which is normally covered by gravity or motorized louvers. The fans vents, or louvers, should be motorized, with their action controlled by fan operation. Motorized louvers prevent the wind from opening the louvers, especially when heat is being supplied to the green house. Wall vents should be placed continuously across the end of the greenhouse to avoid hot areas in the crop zone.

Evaporative cooling in combination with the fans is called as fan-and-pad cooling system. The fans and pads are usually arranged on opposite walls of the greenhouse. The common types of cooling pads are made of excelsior (wood fiber), aluminum fiber, glass fiber, plastic fiber and cross-fluted cellulose material. Evaporative cooling systems are especially efficient in low humidity environments. There is growing interest in building greenhouses combining both passive (natural) and active (forced) systems of ventilation. Passive ventilation is utilized as the first stage of cooling, and the fan-pad evaporative cooling takes over when the passive system is not providing the needed cooling. At this stage, the vents for natural ventilation are closed. When both options for cooling are designed in greenhouse construction, initial costs of installation will be more. But the operational costs are minimized in the long run, since natural ventilation will, most often meet the needed ventilation requirements. Fogging systems is an alternative to evaporative pad cooling. They depend on absolutely clean water, free of any soluble salts, in order to prevent plugging of the mist nozzles. Such cooling systems are not as common as evaporative cooling pads, but when they become more cost competitive, they will be adopted widely. Fogging systems are the second stage of cooling when passive systems are inadequate.

Forced Ventilation